BellaDati Big Data IoT Analytics Solution for Manufacturing

BellaDati Big Data IoT Analytics Solution for Manufacturing delivers unprecedented process efficiency – and saves significant amount of money to organizations of all sizes.

IoT is not about to get insides, it is not enough in today world. Actions and outcomes – both of which need business context to be effective. That is why we have build Belladati IoT Analytics Framework and our partners used this Framework to build flexible industry IoT solutions.

Explore our Big Data Analytics solution for Manufacturing

BellaDati Smart Machine and Other Asset Solutions

The efficiency of the manufacturer is critical, competing on operational excellence is central to your overall strategy. One of the most significant component of value chain, a mounting machine production facility, is suffering from high preventative maintenance costs, any machine outage incurs significant associated opportunity costs. Maintenance services have always been important. But as equipment becomes more complex and automated, therefore IoT application became critical. Our partners have used BellaDati IoT Analytics framework to develop solutions for Machine System monitoring via sensors in combination with predictive maintenance modeling and scheduling that can significantly increase the runtime of assets.

BellaDati Analytics to Increase Efficiency of Production

Our customers use BellaDati Analytics to support continuous improvement in the production efficiency. Belladati helps them to identify areas of the improvement in supply chain, in the production process and in sales as well as in marketing. BellaDati Analytics helps to identify fast deificiencies in the production and helps to set up new targets. BellaDati predictive function are used to set up operational dashboard. Management can access KPI metrics via mobile real time.

Our Analytics for Production Ticketing System

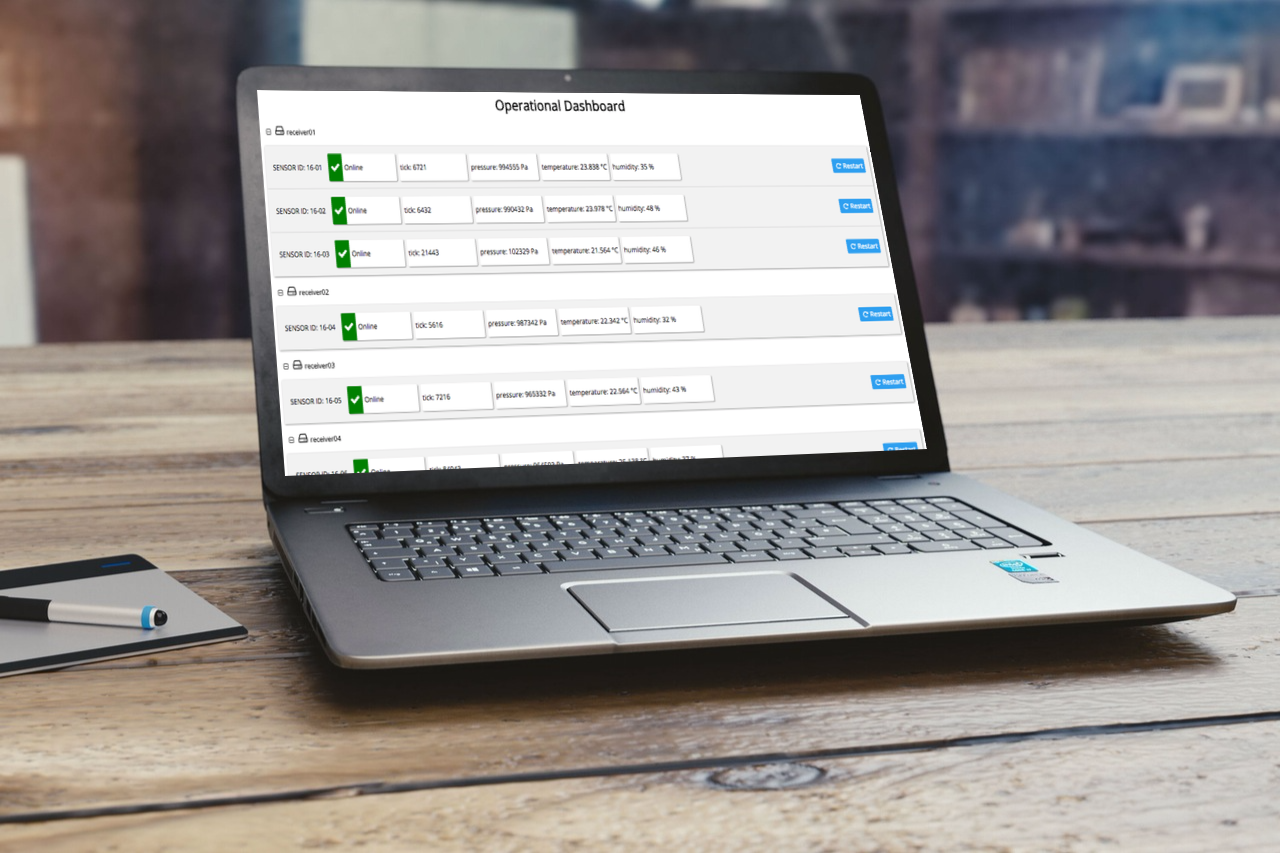

Belladati IoT Analytical Framework helps to increase the uptime of the production line. Our customer uses BellaDati analytics to create the factory ticketing system that allows to track problem resolution turn-around time using real time operational dashboard, analyze trouble tickets (system failures), compare performance for different factory locations, provide additional inputs for predictive maintenance and more. Relevant data from his proprietary manufacturing information systems are loaded to BellaDati database.

BellaDati IoT Analytics Solution for Manufacturing and Predictions

Our robust IoT Data Collector (middleware) is utilized to collect data from various sensors as temperature, moisture, Acc1_1x_Amp, Acc_1x_Phase, Acc2_1x_Amp, Acc2_1xPhase, ClampingPressure, OilFlow, OilPressure, OilTemperature, Puls_1x_Amp, Puls_2x_Amp.

Our robust IoT Data Collector (middleware) was utilized:

- To monitor real-time sensor status and values using operational dashboard.

- To monitor real-time sensor values and raise alerts if semi-critical values are reached.

- To display historical values.

- To predict time to repair and to measure outstanding time to repair until critical values are reached.

- Customers use our solution to monitor the quality of engines during the production. BellaDati IoT Data Collector collects data from sensors that can measure Amp and Phase. Data are collected in 30 subsequent series (each serie has 150 datapoints). Data are stored in BellaDati database, mean, median and standard deviation is calculated, visualized and compared to the calibration.

- Correlations between predictive factors and failures are calculated to identify failure predictors and prevent failures.

Our Analytics for Production Monitoring – Quality of Engines

Customers use our solution to monitor the quality of engines during the production. BellaDati IoT Data Collector collects data from sensors that can measure Amp and Phase. Data are collected in 30 subsequent series (each serie has 181 datapoints). Data are stored in BellaDati database, mean, median and standard deviation is calculated, visualized and compared to the calibration.